MOTI-160XP Copper Busbar Straightener Machine

Copper Busbar Straightener Machine

Copper Busbar Straightener Machine

Technical Parameters of Copper Busbar Straightener Machine

|

Items |

Specification |

Unit |

|

|

Straightening material |

Copper,Aluminum Busbar |

--- |

|

|

Processing Max. Width |

160 |

MM |

|

|

Processing Thickness Range |

2-15 |

MM |

|

|

Number of Straightening Rollers |

Upper Rollers |

6 |

160 |

|

Down Rollers |

7 |

||

|

Roller Rotate Speed |

34 |

RPM |

|

|

Straightening Roller linear speed |

6500 |

mm/min |

|

|

Diameter of Straightening Roller |

φ90 |

MM |

|

|

Working Table Height |

860 |

MM |

|

|

Motor Power |

4 |

Kw |

|

|

Voltage |

380 |

V/AC |

|

|

Outside Dimension |

1300×800×1350 |

MM |

|

|

Weight |

900 |

KG |

|

WORKING PRINCIPLE of Copper Busbar Straightener Machine

This Copper Busbar Straightener machine adopts a multi-roller forced leveling mechanism to

effectively eliminate the sinusoidal movement of the busbars between the upper and lower rows

of power rollers after the sinusoidal movement between the upper and lower rows of power rollers,

effectively eliminating the upper and lower disordered deformation of the busbars and the internal existence.

The stress eventually makes the busbars tend to be nearly straight and achieve a good leveling effect.

2 . The Copper Busbar Straightener machine is mainly used to straighten the copper and aluminum busbars before punching, shearing/cutting and bending to improve the quality of the workpiece.

3 . This equipment is highly efficient and is an indispensable equipment in the switch industry.

STRUCTURE OF Copper Busbar Straightener Machine

1 . This machine is a two-row shaft roller leveling machine.

It is mainly composed of a frame, an upper roller row seat, a lower roller row seat, a transmission mechanism, an adjustment mechanism and the like.

2 . In the work, the motor is driven by the reduction gear box, and the transmission roller shaft in the upper and lower roller row seat is driven by the chain drive to realize the function of straightening the bus bar.

3 . The power in the transmission chain is transmitted to the straightening roller shafts in the upper and lower roller rows by the upper and lower chains, so that the roller shafts of the upper and lower roller rows are all power rollers.

4 . This Busbar Straightener machine works stably.

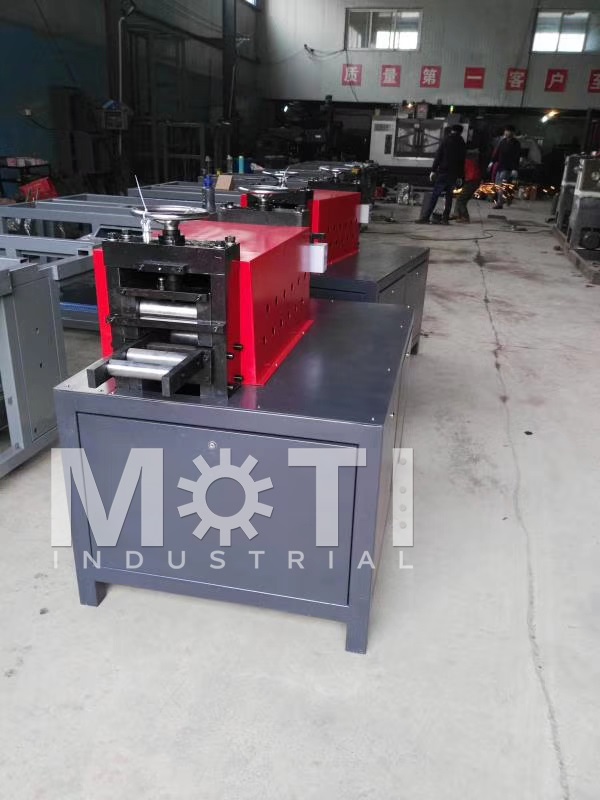

Workshop of Factory

Contact US

JINAN MOTI BUSBAR MACHINERY CO.,LTD

Email: forrest@motiindustrial.com / sale@busbarbendingmachines.com

www.motiindustrial.com

www.busbarbendingmachines.com

Address:11th Floor East Ring International Plaza Tower A, Licheng District,Jinan,Shandong,China