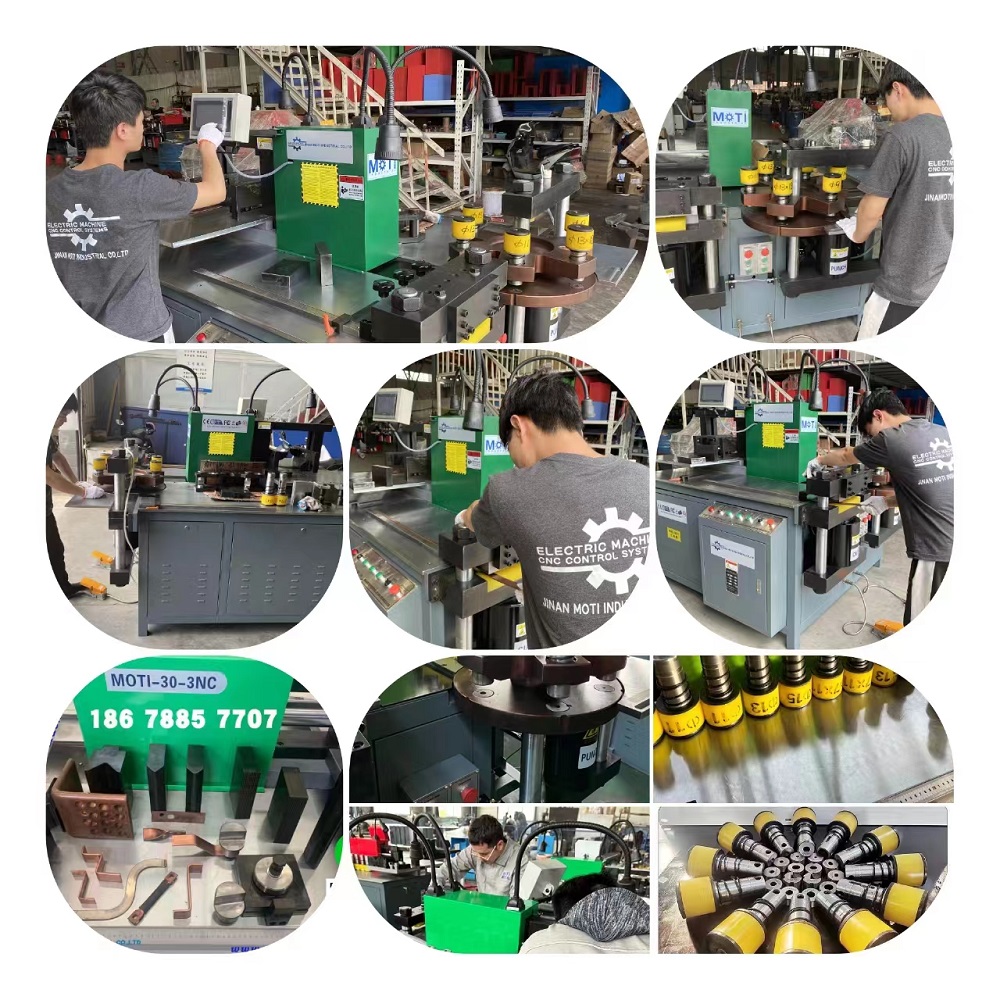

Busbar fabrication machine

MOTI busbar machine adopts German Siemens CNC control system.

Especially the bending function, it can quickly and easily perform various processing on copper and aluminum busbars, such as plane/horizontal bending, vertical bending, U-shaped bending, embossing, flat pressing, stranding, cable connector processing, etc.

At the same time, it also has punching and cutting functions.

The cutting unit adopts a double-column structure, with flat cutting, no waste, no burrs, and no leg collapse.

The punching unit adopts a six-die tooth turntable, which eliminates the need for frequent die changes, saves time, and has a good processing view.

Address:11th Floor East Ring International Plaza Tower A, Licheng District,Jinan,Shandong,China